At EGA Solutions® we develop solutions integrating our own 4.0 technological resources that serve to manage, control and analyze assets and production processes. All this remotely, centralized and integrated.

See more

See more

At EGA Solutions® we develop solutions integrating our own 4.0 technological resources that serve to manage, control and analyze assets and production processes. All this remotely, centralized and integrated.

See more

See more

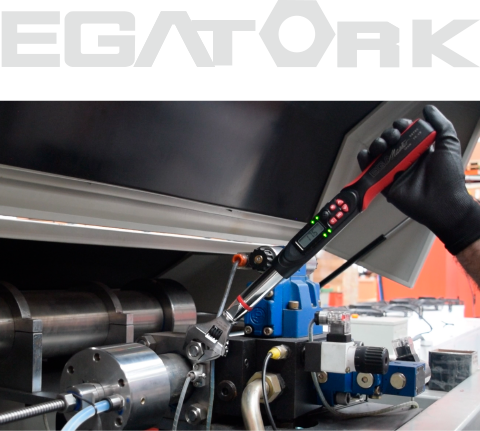

Torque management system, based on software and automated wireless tools, with the aim of:

A management system for tools and supplies that allow better access control to tools, as well as the entry and exit of them during work shifts.

Traceability of tools; access and movement control

Management of certifications and recalibrations

Location control

Built-in procurement request

Connectivity: able to send reports and alarms. Remote connection

Central lock

Tool and tooling management system, automated using RFID technology, which allows better control of access to tools, as well as their entry and exit during work shifts.

Automated tracking Management Technology

Traceability of tools; access and movement control

Management of certifications and recalibrations

Location control

Built-in procurement request

Connectivity: able to send reports and alarms. Remote connection

Central lock

Descentralized tool and tooling management system, automated using RFID technology, which allows better control of access to tools, as well as their entry and exit during work shifts.

Decentralized and multi-case system

Automated tracking Management Technology

Traceability of tools; access and movement control

Management of certifications and recalibrations

Location control

Built-in procurement request

Connectivity: able to send reports and alarms. Remote connection

Central lock

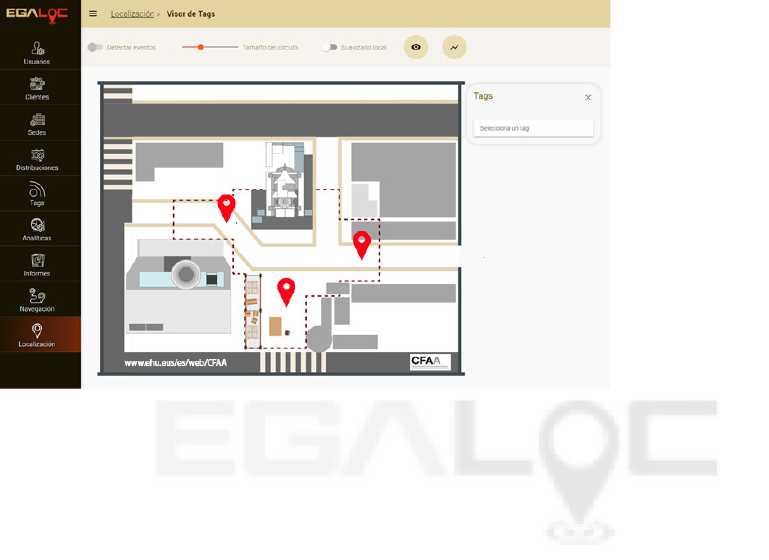

Geolocation solution for locating equipment and products (both finished and in progress) in production plants.

The solution includes:

Management systems for consumable and semi-consumable materials in different types of KANBAN warehouses.

The solutions offers:

Access control

Real-time consumption management

Cost reduction

Full traceability

24 h service

Customized solutions to implement Lean Manufacturing, 5S & Poka Yoke.

Systems, which allow: